A 典型加工件示例

A 典型加工件示例

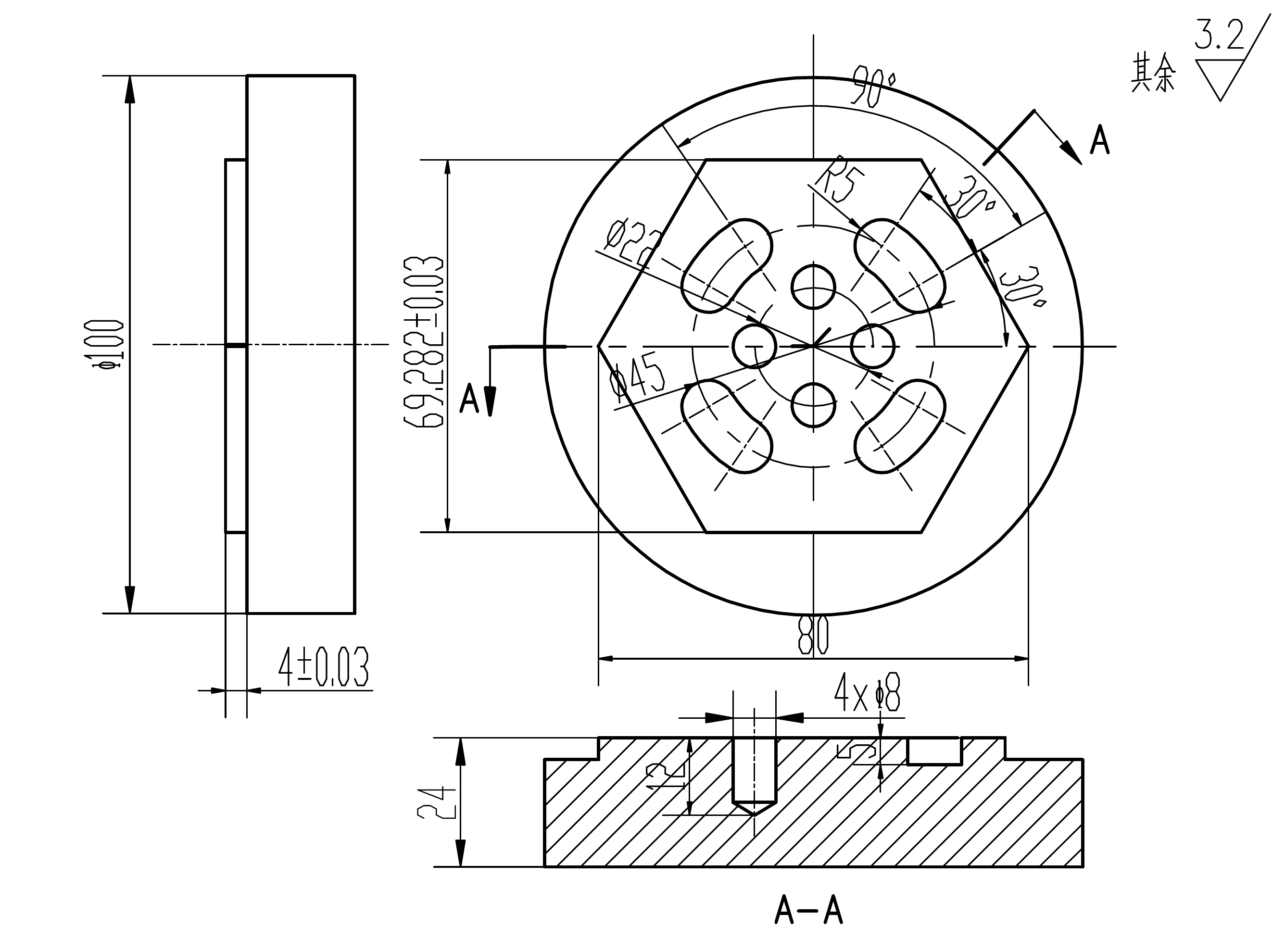

示例图纸:

加工过程:

- Φ16平底铣刀铣上表面

- Φ16平底铣刀铣Φ100外圆

- Φ16平底铣刀粗铣六边形凸台

- Φ16平底铣刀精铣六边形凸台

- Φ8平底铣刀粗精铣R5环型槽

- Φ8钻头钻4×Φ8孔

加工程序:

N10 T1 M06 ; Φ16平底铣刀

N20 M03 S1600

N30 G90 G17

N40 G54

N50 G00 Z50

N60 X60 Y-50

N70 CYCLE71 (20, 0.5, 3, 0, -50, -50, 100, 100, 0, 0.5, 10, 0, 1200, 11)

N80 G00 Z50

N90 M05

N100 M03 S1800

N110 G00 X65 Y0

N120 CYCLE77 (10, 0, 5, -24, 100, 0, 0, 3, 0, 0, 1000, 600, 2, 1, 105)

N130 G00 Z50

N140 M05

N150 M03 S1600

N160 G00 X-90 Y18

N170 CYCLE72 ("hexagon", 10, 0, 5, -4, 1, 0.25, 0.1, 1000, 600, 1, 41)

N180 G00 Z50

N190 M05

N200 M03 S1600

N210 G00 X-90 Y18

N220 CYCLE72 ("hexagon", 10, 0, 5, -4, 1, 0, 0, 800, 800, 2, 41)

N230 G00 Z100

N240 M05

N250 T2 M06 ; Φ8平底铣刀

N260 M03 S3500

N270 G00 Z50

N280 X0 Y0

N290 SLOT2 (10,0,5,-5,5,4,30,10,0,0,22.5,30,90,1000,400,0.5,3,0.2,10,1,800,3500,3000)

N300 G00 Z100

N310 M05

N320 T3 M06 ;Φ8钻头

N330 M03 S1800

N340 G00 X20 Y20 Z50 F270

N350 MCALL CYCLE83 (10, 0, 3, -12, 12, -4, 4, 4, 1, 1, 1, 1)

N360 X11 Y0

N370 X0 Y11

N380 X-11 Y0

N390 X0 Y-11

N400 MCALL

N410 G00 Z50

N420 M05

N430 M30

子程序hexagon.iso:

N10 G01 X-78.696 Y10.129

N20 X-30 Y17.321

N30 X-20 Y34.641

N40 X20

N50 X40 Y0.

N60 X20 Y-34.641

N70 X-20

N80 X-40 Y0.

N90 X-30 Y17.321

N100 X-28.5 Y19.919

N110 X-46.362 Y64.725

N120 RET