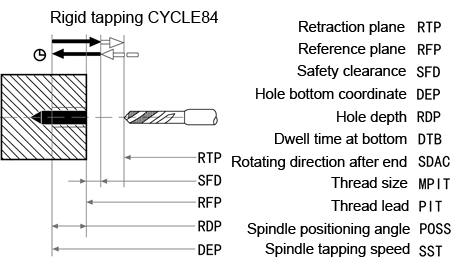

5.2.4 Rigid tapping CYCLE84

Programming:

CYCLE84 (RTP, RFP, SFD, DEP, RDP, DTB, SDAC, MPIT, PIT, POSS, SST, SSR)

Parameters:

|

RTP |

Real |

Retraction plane (absolute) |

|

RFP |

Real |

Reference plane (absolute) |

|

SFD |

Real |

Safety clearance (enter without sign) |

|

DEP |

Real |

Final drilling depth (absolute) |

|

RDP |

Real |

Final drilling depth relative to the reference plane (enter without sign) |

|

DTB |

Int |

Dwell time at thread depth (chip breakage) |

|

SDAC |

Int |

Direction of rotation after end of cycle Values: 3, 4 ,5 or 19 (for M3, M4, M5 or M19) |

|

MPIT |

Real |

Thread lead as a thread size (signed): Range of values 3 (for M3) to 48 (for M48); the sign determines the direction of rotation in the thread |

|

PIT |

Real |

Thread lead as a value (signed) Range of values: 0.001 ... 2000.000 mm); the sign determines the direction of rotation in the thread |

|

POSS |

Real |

Spindle position for oriented spindle stop in the cycle (in degrees) |

|

SST |

Real |

Speed for tapping |

|

SSR |

Real |

Speed for retraction |

Fig.5.5 CYCLE84

Function:

The tool drills at the programmed spindle speed and feedrate to the entered final thread depth.

Note

CYCLE84 can be used if the spindle to be used for the boring operation is technically able to be operated in the position-controlled spindle operation.

Sequence:

1. Approach of the reference plane brought forward by the safety clearance by using G00

2. Oriented spindle stop (value in parameter POSS)

3. Tapping to final drilling depth and speed SST

4. Dwell time at thread depth (parameter DTB)

5. Retraction to the reference plane brought forward by the safety clearance, speed SSR

6. Retraction to the retraction plane with G00; spindle mode is reinitiated by reprogramming the spindle speed active before the cycle was called and the direction of rotation programmed under SDAC

Explanation of the parameters:

1. RTP,RFP,SFD,DEP,RDP, see CYCLE81;

2. DTB(dwell time): The dwell time must be programmed in seconds. When tapping blind holes, it is recommended that you omit the dwell time.

3. SDAC(direction of rotation after end of cycle): The direction of the spindle rotation after end of cycle must be programmed under SDAC.

4. MPIT and PIT(thread lead as a thread size and as a value): The value for the thread lead can be defined either as the thread size (for metric threads between M3 and M48 only) or as a value (distance from one thread turn to the next as a numerical value). The parameter not required in each case is omitted in the call or is assigned the value zero. If the two lead parameters have conflicting values, alarm 61001 "Thread lead wrong" is generated by the cycle and cycle execution is aborted.

5. RH or LH threads are defined by the sign of the lead parameters:

1)Positive value → right (M03)

2)Negative value → left (M04)

6. POSS(spindle position): In the cycle, the spindle is oriented and stopped, and brought into position control before tapping with the SPOS command.

7. SST(speed): Parameter SST contains the spindle speed for the tapping block.

8. SSR(retraction speed): Parameter SSR contains the spindle speed for retraction.

Note

The direction of rotation when tapping in the cycle is always reversed automatically.

Example:

The program machines rigid tapping with cycle CYCLE84. The drilling axis is always the Z axis. Programming zero point is the center of end face. Dwell time is 1 second. A metric thread M6 is tapped.

|

N10 G00 G90 G17 G40 T1 D1 S400 M03 |

Specification of technology values |

|

N20 G94 G01 Z10 X0 F50 |

Approach drilling cycles starting position |

|

N30 CYCLE84(10, 0, 1, -20, 20, 1, 3, 6, 0,0, 300, 600) |

Cycle call |

|

N40 G00 Z10 |

Next position |

|

N50 M02 |

End of program |