6.1 Outer contouring

Article Number: 526 | Rating: Unrated | Last Updated: Fri, Aug 26, 2016 3:43 PM

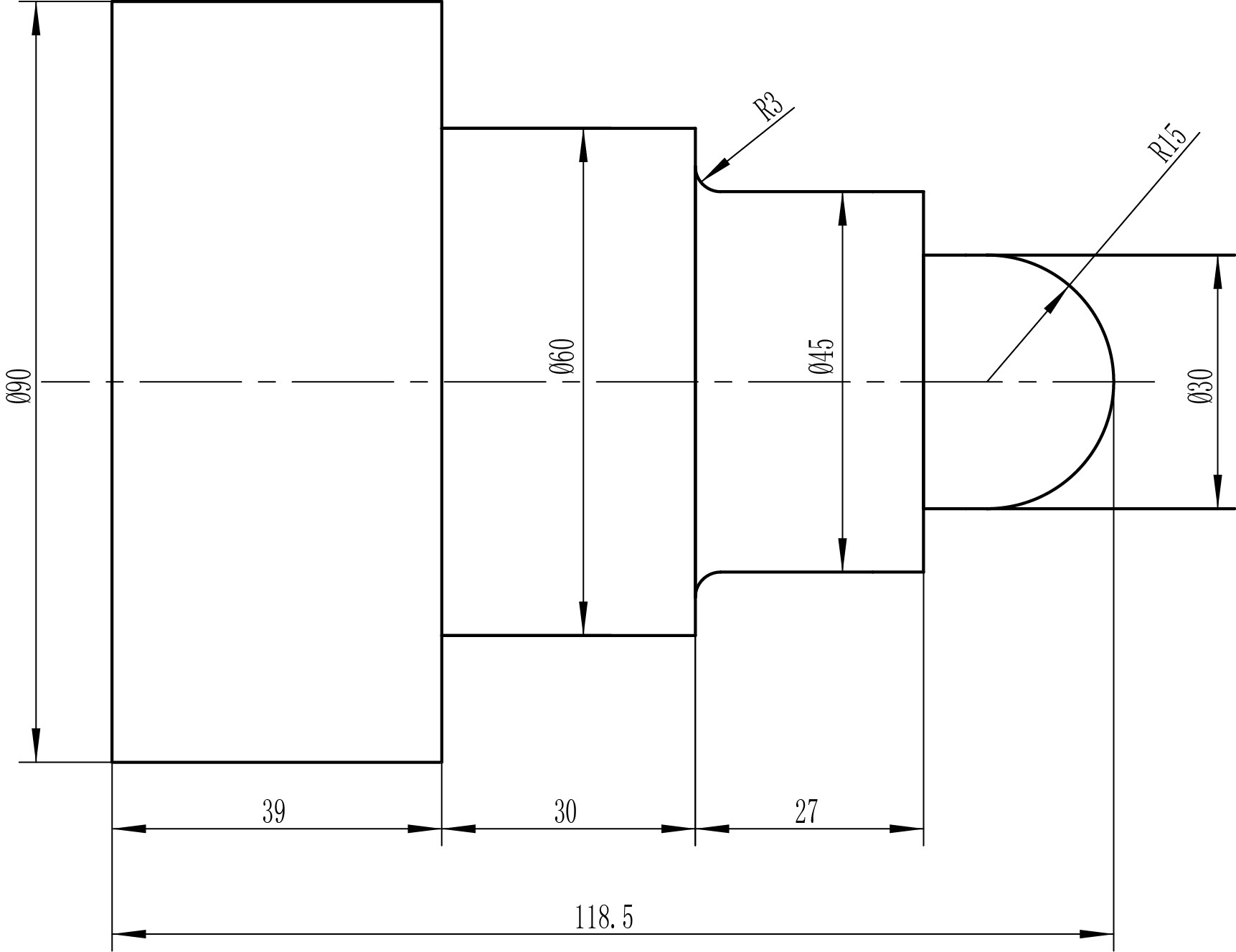

Example drawing:

Processing:

1. T1 rough turning outercylindrical

2. T2 finish turning outercylindrical

Machining program:

N10 T1 D1

N20 M03 S600

N30 G95 F0.2

N40 G00 X100 Z2

N60 G00 X100

N60 G00 X100

N70 Z100

N80 M01N90 T2 D1

N100 M03 S800

N110 G00 X100 Z2

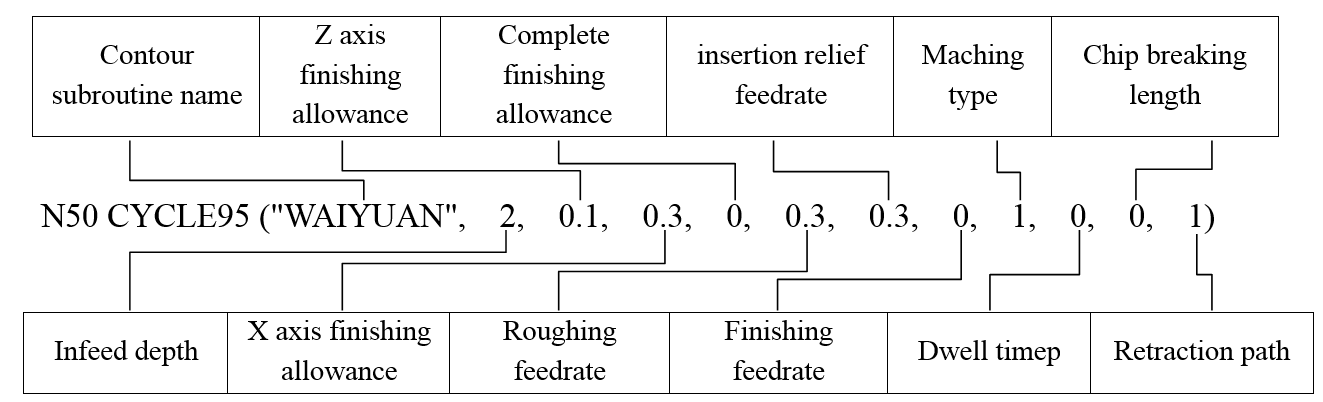

N120 CYCLE95 ("WAIYUAN", 0, 0, 0, 0, 0, 0, 0.15, 5, 0, 0, 1)

N130 G00 X100

N140 Z100

N150 M5

N160 M30

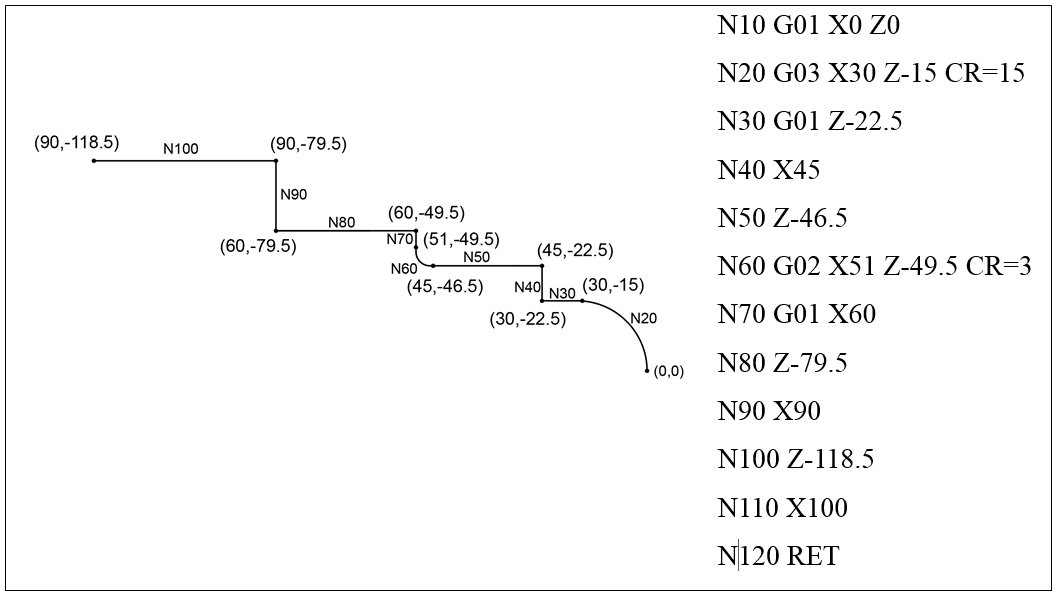

subroutine WAIYUAN.iso: