1.1 Coordinate systems

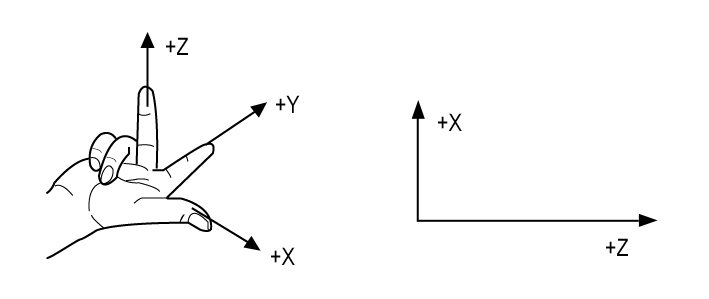

For machine tools, right−handed, right−angled coordinate systems are used, as shown in Fig.1.1. The movements on the machine are described as a relative movement between tool and workpiece.

Fig.1.1 Coordinate systems

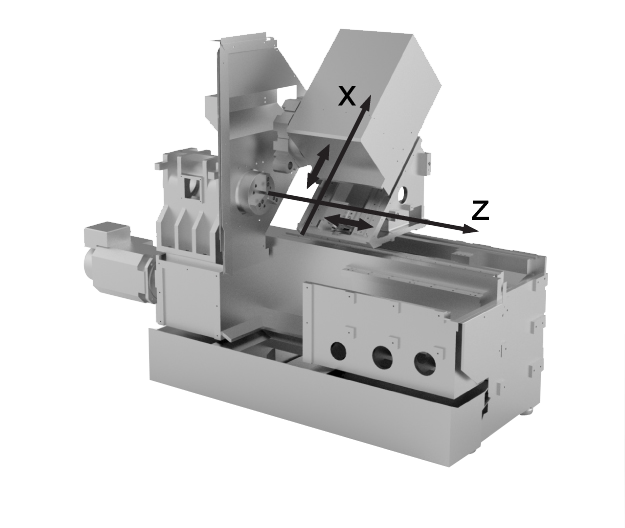

Fig.1.2 Coordinate system of a turning machine

Coordinate system of a turning machine is shown as Fig.1.2. The origin of the coordinate system is the machine zero, Z-axis coincides with the spindle center axis, the positive direction is away from the spindle face; X-axis perpendicular to the spindle axis, the positive direction is away from the spindle center.

Common lathe system coordinate system is defined as follows:

1. Machine coordinate system MCS: The origin of the coordinate system is the machine zero. This point only represents a reference point defined by the machine manufacturer. Machine determine the MCS by returning the referencepoint.

2. Workpiece coordinate system WCS: The coordinate system is used to describe the geometry of a workpiece in the workpiece program. The workpiece zero can be freely selected by the programmer in the Z axis. In the X axis, it lies in the turning center.